Take training courses delivered by Champagne experts

Through our partner centres, selected and trained by the Comité Champagne, you, as wine professional, can follow the "Champagne Specialist" course and enjoy a wealth of practical experience and tastings.

Online training

Train online with the Champagne MOOC: a complete course leading to a diploma.

Guided by Jérémy Cukierman, Master of Wine 2017, and accompanied by industry specialists, you will gain a wealth of knowledge about Champagne, its history, terroir, winemaking, the diversity of its wines and how to taste them.

Train your teams or students with our bespoke services

Are you a wine distributor, a chain of wine shops, a hotel group, etc. looking to train your teams in the wines of Champagne? Are you a teacher at a hotel management school looking for a lesson for your students? Experts from the Comité Champagne can offer a range of bespoke training courses to enhance the skills of your teams or students.

Test your knowledge of Champagne

With a series of quizzes and a "serious game", you can test your knowledge of the most famous sparkling wine.

Learning resources

Thematic fact sheets, videos and webinars to view or download

Do you have a question about our Champagne training courses? Would you like to register for an online or face-to-face course? Take a look at our Frequently Asked Questions (FAQs) you will find many answers.

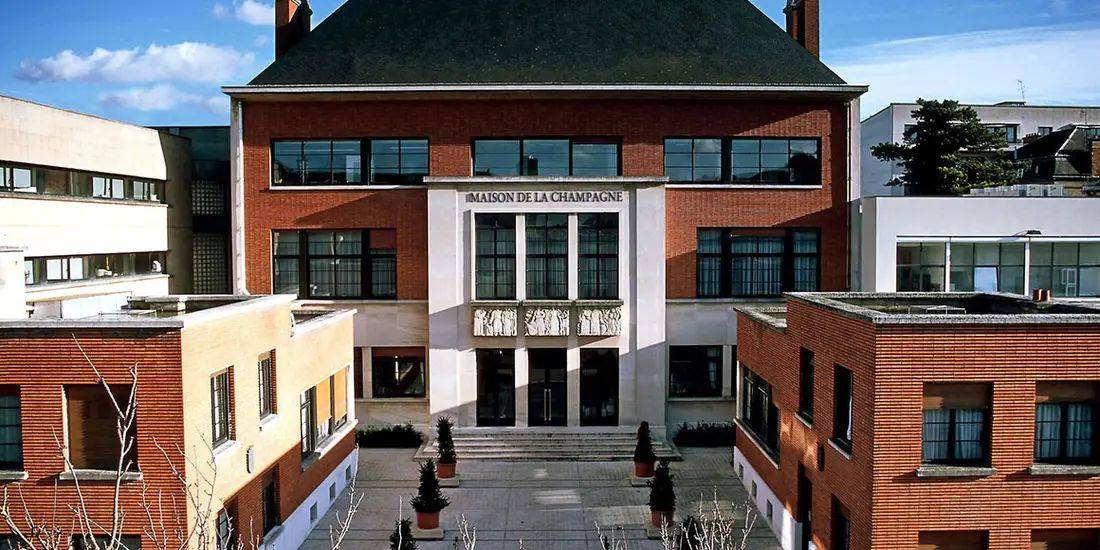

Champagne Education was set up by the Comité Champagne, the inter-professional body that brings together the Winegrowers and Houses of Champagne. It offers both online learning and face-to-face courses so that anyone can learn about the wines of Champagne.

All our online training courses are financed by the Comité Champagne and can thus be offered free of charge to all learners. Face-to-face training at our partner centres can be financed by learners or their employers.

The Comité Champagne recommends responsible consumption, combining knowledge, pleasure, respect and self-control. Visit our dedicated page to find out more about responsible tasting.

Viewpoints and Opinions

Anna-Maria - Sommelier

“The Champagne Challenge in Milan was a new experience for me and very enjoyable.”

⭐⭐⭐⭐

Gregory - Maître d'hôtel

“Champagne Specialist has enabled me to improve my technique when it comes to pairing food and Champagne.”

⭐⭐⭐⭐⭐

Clémence - Wine buyer

“During the course, I was able to deepen my knowledge of this very special wine, particularly through the workshops.”

⭐⭐⭐⭐⭐

Simone - Wine shop manager

“It’s a really good course, great fun and it teaches a lot of skills.”

⭐⭐⭐⭐⭐